What should I do when checking my tyres?

Tyre checks should be made every month as well as before making any long journeys by using a reliable and accurate tyre pressure gauge.

Always measure tyre pressure when tyres are “cold”. Tyres are cold if they have not been driven for more than 2 miles at low speed or have been stationary for a least two hours.

Tyre checks should include:

- Checking the tread depth meets the legal minimum depth

- Checking the tyre pressure meets vehicle manufactures’ recommendations

Read our Tyre Pressure guide to find out more.

- Checking the overall condition

At the same time as checking your tyre pressure and tread depth, examine the tyres for any cuts or bulges which must be assessed by a professional if found – a bulge in a tyre indicates internal structural damage and must be replaced. The tyre must also be replaced if you find any cuts deep enough to reveal the internal structure of the tyre.

Checking your vehicles tyre tread depth

Why is measuring tyre tread depth important?

If tyre tread depth wears below 3mm, ability to grip the road is reduced and stopping distances increase dramatically, therefore checking the measurements at least once a month and before long journeys is vital.

Driving with worn tyres is a serious safety risk and can be costly too. In the UK if your tyre is below the legal limit, you could get a £2,500 fine plus three points on your licence, per tyre.

What is the minimum legal tread depth?

Cars, vans and LCV

![]()

The current law for the tread depth for cars, vans and LCV is to have a minimum depth of 1.6mm across the central three-quarters of the tyre and around the entire circumference.

It is recommended to increase the safety of the car to replace the tyres before the 1.6mm limit is reached. Many vehicle manufactures’ suggest replacing the tyres when they reach 3mm.

Trucks and vehicles exceeding 3.5 tonnes

![]()

For any vehicles exceeding 3.5 tonnes the current law states that the tread should be a minimum of 1mm across the central three-quarters of the tyre and around the entire circumference.

Motorcycles

![]()

Motorcycles over 50cc the minimum tread is 1mm across three-quarters of the width of the tread pattern and a visible tread on the remaining quarter. Motorcycles up to 50cc are required to have all grooves of the original tyre pattern clearly visible.

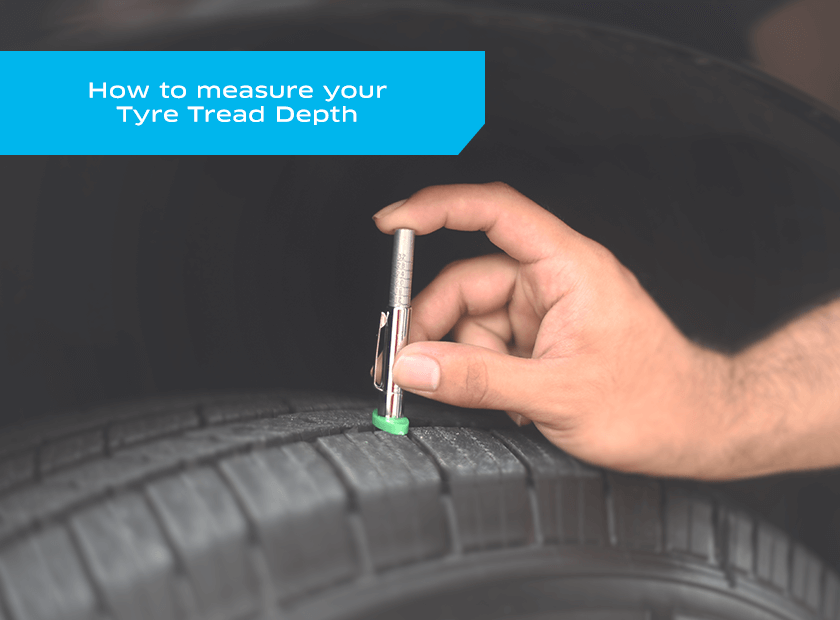

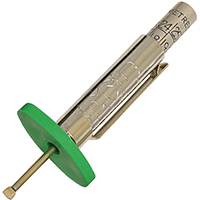

How to measure your tyre tread depth with a gauge

You can carry out a visual check of the tread wear indicators to assess the levels of your tread depth. These indicators are small raised areas at the bottom of the grooves on your tyres. If the surface of the tread rubber is level with these raised areas, the tyre tread depth is approaching the legal limit and you should have your tyres checked and replaced.

However, using a tyre tread depth gauge will provide a more accurate measurement and is simple to do.

- Extend the measuring probe on the tread depth gauge as far as it will go.

- Place the probe into the tread groove, making sure not to place it on the tread wear indicators or any raised surfaces of the tread design. Push down on the gauge’s base.

- Check the measurement is above 1.6mm. If you are using an analogue gauge this will be shown on a scale. If it’s digital the reading will be displayed on a screen.

- Measurements must be taken around the whole circumference of the tyre and across the central three-quarters of the width of the tyre.

- Repeat the process on every tyre.