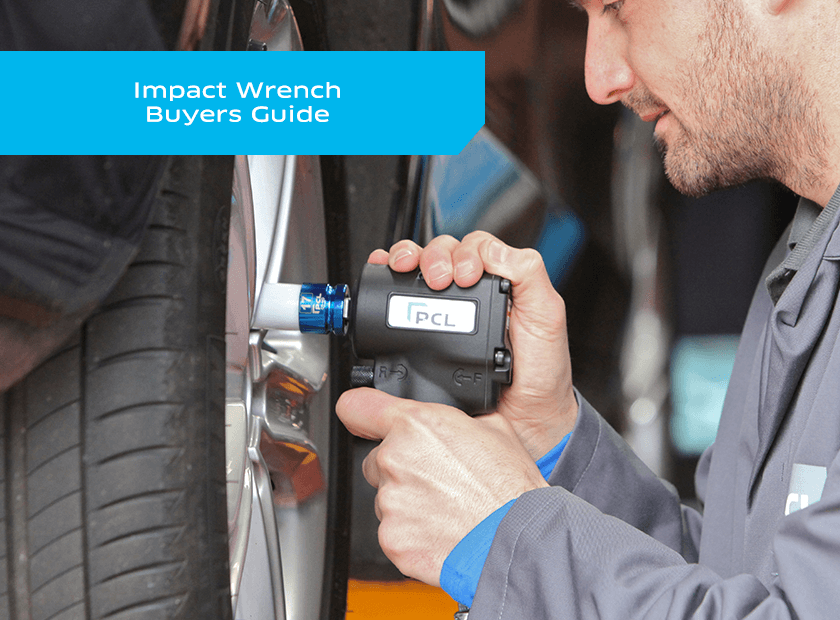

Impact Wrench Buyers Guide

This guide covers:

- An overview including what an impact wrench is used for, how it works and the difference between impact wrenches, impact drivers and impact ratchets

- How to select the right impact wrench for your application including the difference between PRESTIGE and PRO Impact Wrenches and factors to consider

- How to maintain an impact wrench

- Safety tips

Impact Wrench Overview

What is an impact wrench used for?

Designed to effortlessly deliver high torque output used to loosen or tighten bolts, lug nuts and fasteners, Impact Wrenches are used in a wide range of environments from DIY enthusiasts to professionals in tyre shops, heavy plant/ equipment maintenance, assembly, construction - generally anywhere that requires extra powerful tools.

How does it work?

An Impact Wrench features an electric or air motor that applies short bursts of a twisting motion that is effective at loosening (or tightening) bolts.

The high torque output is produced through a hammering action at a low speed – rather than constant rotations at high speed like that of an air drill.

What is the difference between impact wrenches, impact drivers and impact ratchets?

The main difference between an impact wrench and impact driver is that an impact wrench features a square drive and can be fitted with different sizes of impact sockets which fit onto a wheel lug. Alternatively, an impact driver features a hex driver and is used for driving screws.

An Impact Ratchet also has a square drive, however there is a smaller range of drive sizes for ratchets; 1/4, 3/8 or 1/2 inch, whereas Impact Wrenches are available with either a 1/4, 3/8, 1/2, 3/4 or 1 inch drive.

Impact Wrenches are generally heavier and provide more power (torque) than impact drivers and ratchets.

Since Impact Ratchets provide a lower torque output than an Impact Wrench, they are ideal for tightening and removing smaller lug nuts and bolts. Impact Ratchets are also smaller in size and lighter in weight, this gives the user greater control and makes ratchets perfect for work in confined spaces such as small engine repairs and transmission work.

|

MINI Air Ratchets |

PRESTIGE Air Ratchets |

|

PRO Air Ratchets |

PRESTIGE Lumphammer Ratchet |

How to select the right impact wrench for your application

What is the difference between PRESTIGE and PRO Impact Wrenches?

You may notice PCL’s Impact wrenches belong to either the PRESTIGE or PRO range.

The PRESTIGE range is PCL’s premium range of air tools which provides the ultimate in performance for the serious professional user. Impact wrenches in this range can be distinguished by the black/grey and blue design and feature an ergonomic handle and lightweight body - designed to reduce fatigue during prolonged periods of usage therefore ideal for environments such as tyre shops, who frequently use Impact Wrenches. Tools in this range, also have reduced noise and vibration output compared to other tools on the market.

PCL’s PRO range is aimed at the everyday tradesman who requires a price competitive air tool without the worry of compromising on quality or performance. Specifically designed to withstand the rigours of day to day use in the heaviest of workshop and tyre environments, PCL’s PRO range delivers without exception.

Factors to consider when selecting an impact wrench

Drive Size

When purchasing an impact wrench, you will need to consider the drive size.

Impact wrenches are available in the following sizes: 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch or 1 inch.

The smallest sizes, 1/4 and 3/8 inch are ideal for working in confined spaces and more suitable for where accuracy and precision is key.

PCL's 3/8 inch Impact Wrenches

The most common size is 1/2 inch as it is suitable for most applications. The 1/2 inch will provide enough power and precision when working with regular-sized vehicles.

PCL's 1/2 inch Impact Wrenches

The most powerful Impact Wrenches tend to be 3/4 or 1 inch, and are commonly used in industrial applications such as construction and large tyre applications.

PCL's 3/4 inch Impact Wrenches |

PCL's 1 inch Impact Wrenches |

PCL's APP271 PRESTIGE 1 inch Impact Wrench in use

Whichever size you decided, remember to always select the right impact socket and you should never use a regular socket.

Torque

It is highly important to consider torque when selecting an air impact wrench.

Using an impact wrench with a higher torque than necessary can result in over-tightening of nut and bolts, which could lead to severe damage. Not enough torque is also highly dangerous as it leads to under-tightening which could result in a wheel nut becoming loose when the car is driving down the road.

What torque does your application require? If you are unsure, then we recommend referring to the manufacturers manual or packaging of the component that you are tightening.

If using an impact wrench or similar impact tool, it is recommended to check the nut with a manual torque wrench for precise accuracy.

High Torque Impact Wrenches

|

Part No. APP210S |

Part No. APP234 |

Part No. APT266 |

Weight

If you plan to use the air tool over long periods, it is important to select a well-balance tool that is comfortable and lightweight enough to hold over several hours.

Lightweight Impact Wrenches

|

Part No. APP200 |

Part No. APP101 |

Part No. APP271 |

Sound

Prolonged exposure to loud noise can result in irreversible damage to your hearing, therefore if you plan to use the tool over long periods it is recommended to select a tool with lower noise levels where possible. Hearing protection must always be worn for exposures above 85 dBa.

Low Noise Impact Wrenches

|

Part No. APP210S |

Part No. APT105 |

Part No. APT233 |

Vibration

For a safer and more comfortable experience, opt for a lower vibration level if you plan to use the tool over long periods regularly as high exposure to hand-arm vibration can lead to permanent health effects.

Low Vibration Impact Wrenches

|

Part No. APP200 |

Part No. APT205 |

Part No. APT266 |

Compressor tank size

Consider how you are going to power the tool and ensure that the compressor is suitable for the tool and application.

Generally using a tool that operates in short bursts like an impact wrench, 6 seconds. The table below shows how many seconds each PCL impact wrench should run with various size compressors.

|

Part No |

Description |

stated cfm |

24 l |

50 l |

100 l |

150 l |

200 l |

|

PRESTIGE 1/2 inch Heavy Duty Impact Wrench |

6.5 |

4 |

8 |

16 |

24 |

33 |

|

|

PRESTIGE 1/2 inch Stubby Impact Wrench |

4.3 |

6 |

12 |

25 |

37 |

49 |

|

|

PRESTIGE 1/2 inch Impact Wrench |

2.7 |

9 |

20 |

39 |

59 |

78 |

|

|

PRO 1/2 inch Impact Wrench |

3.6 |

7 |

15 |

29 |

44 |

59 |

|

|

PRO 1/2 inch Aluminium Impact Wrench |

3.9 |

7 |

14 |

27 |

41 |

54 |

|

|

PRO 1/2 inch Composite Impact Wrench |

4.8 |

5 |

11 |

22 |

33 |

44 |

|

|

PRESTIGE 3/8 inch Impact Wrench |

9.6 |

3 |

6 |

11 |

17 |

22 |

|

|

PRO 3/8 inch Impact Wrench |

3 |

8 |

18 |

35 |

53 |

71 |

|

|

PRESTIGE 3/4 inch Impact Wrench |

6.9 |

4 |

8 |

15 |

23 |

31 |

|

|

PRESTIGE 1 inch Impact Wrench |

9.6 |

3 |

6 |

11 |

17 |

22 |

|

|

APT265 |

PRO 1 inch Pistol Grip Impact Wrench |

11 |

2 |

5 |

10 |

14 |

19 |

|

PRO 1 inch Hercules Impact Wrench with 200mm Extended Shank |

9.5 |

3 |

6 |

11 |

17 |

22 |

See our handy guide on selecting the right compressor for more details.

Download the comparison of all PCL Impact Wrenches

How do I maintain an Impact Wrench?

All servicing and repairs must be carried out by qualified service technicians.

Make sure your impact wrench is lubricated

Don’t forget to oil the impact wrench the first time you use the tool from new.

Lubrication is an important aspect of air tool maintenance.

Remember to add a few drops of air tool oil into the air inlet, this should be carried out before and after use daily to prevent rust build up.

If the impact wrench is frequently used, it is recommended to fit a lubricator at the final stage downstream on the air supply after any filtration. In-line lubricators such as the INL6 can be connected on the tool or hose itself.

You should only use clean, dry, regulated compressed air as a power source for an impact wrench. Read our handy guide on why it is important to use FRL units and how to choose the correct air treatment unit.

PCL's APP210S Impact Wrench with INL6 In-line Lubricator

Never use the incorrect sockets

To achieve optimal tool efficiency and ensure safety, it is important to only use correctly sized impact sockets on impact wrenches.

You should never use regular sockets on impact sockets as this can cause damage to the anvil – more detail can be found in our handy guide.

1/2", 3/4" & 1" Impact Sockets Sets |

Clean the impact wrench regularly

It is important to keep the body of the impact wrench clean and free from debris as accumulated dirt can cause misalignment or jamming of the parts, which can damage the tool itself.

Remember to inspect the impact wrench as well as hose and fittings regularly and before use.

After every use, wipe clean and safely store the tool.

Tip – Use an air blowgun to clean off any debris from equipment. Never point a blowgun towards yourself or anyone else.

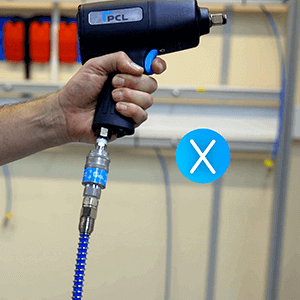

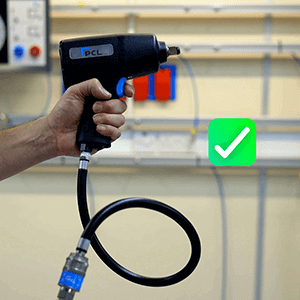

Protect your equipment

Safety guidelines recommend fitting an Air Tool Whip Hose between the air tool and the coupling, this will protect against whip hose and prolong the life of your couplings.

Read more on the importance of using an air tool anti-whip hose.

|

|

|

|

|

|

Wear eye and ear protection at all timesLong term exposure to noise produced from the operation of air tools can lead to permanent hearing loss. Air and power tools are capable of propelling materials such as metal chips, saw dust and other debris at high speed, which could result in serious eye injury. To prevent this, it is important to wear PPE equipment when using impact wrenches |

|

Prevent the risk of entanglementNever wear loose clothing or jewellery when using an air tool. Remember to tie or cover hair before use, as tools which contain moving elements or drive other moving tools, such as impact wrenches, grinders, etc, can become entangled in hair, clothing, jewellery and other loose objects, resulting in severe injury. |

|

Inspect the impact wrench and accessories for damageYou should never use damaged tools or accessories; this can result in serious injuries. Before using an impact wrench, inspect the tool for any cracks, breakage or other signs of damage. Replace or repair any damaged equipment. Repairs must only be carried out by qualified service technicians. |

|

Remember to disconnect the impact wrench when not in useNever change accessories such as sockets when the impact wrench is still connected to the compressed air. This can cause serious injuries if the tool switches on by mistake. |

|

Prevent whip hoseAs mentioned earlier, it is recommended to use an anti-whip hose to prevent whip hose. The Health and Safety Executive also recommends the use of a Safety Self-venting Coupling to prevent accidental tool operation and uncontrolled whipping of the hose. |

|

Only ever use impact sockets with impact wrenchesFor more information, read our guide on the difference between impact and regular sockets and why you should only ever use impact sockets with air tools. |