James Stopps to focus on strengthening pneumatic company’s distributor network

As the newest addition to…

Continue Read

Blog

Unfortunately our site is not compatible with Internet Explorer.

To continue using our site, please use a different browser.

-

UNITI Expo, Messe Stuttgart, Germany, 14th–16th May 2024Continue Read

-

Document Number PCN2401 – 13 March 2024 This is the official notification that Pneumatic Components Ltd is changing the TDG16 Tyre Tread Depth Gauge. This notification provides information…Continue Read

-

Pneumatics expert teams up with outdoor activity specialist PCL’s recently launchedContinue Read

-

Mobile ‘showcase’ will take products and training to customers, trade shows and open daysContinue Read

-

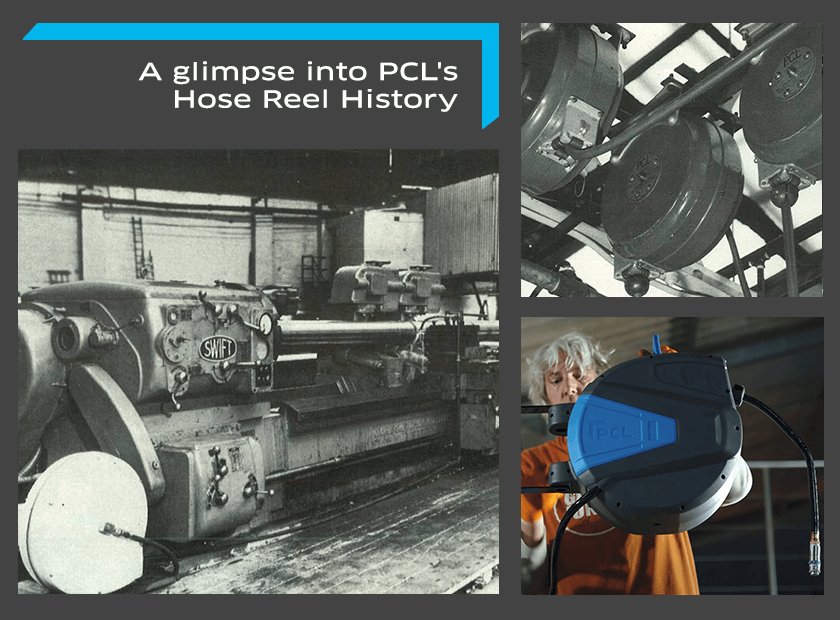

A glimpse into PCL's Hose Reels History A staple of the highly-regarded PCL product range throughout the years has always been our…Continue Read

-

Categories: Obsolete NotificationDocument Number OBNPCL2306 – 14th December 2023 This is the official notification that Pneumatic Components Ltd is discontinuing its Sand Blasting Gun. This notification provides information on the affected items, the important dates…Continue Read

-

Product launch reinforces commitment to UK manufacturing Pneumatics expert PCL is proud to reinforce its commitment to UK…Continue Read