The Basics About Blowguns

PCL’s versatile range of air blowguns are designed to be used in a wide range of applications. Here we look at the different types available and how to select the right one for your application.

Where are they used?

Commonly used in laboratories and manufacturing industries but also workshops and car body shops, for a range of jobs from tyre fitting to paint spraying. Blowguns are fitted to a compressed air line to produce a jet stream of air, they are used to quickly and efficiently clear equipment and surfaces of debris such as dust or chips, with the nozzle directing the air flow.

What is the law relating to using compressed air blowguns?

There is no current legislation relating to the use of blowguns, nor is there any specific legal restriction regarding the type of blowgun that should or should not be used.

However, there are laws which must be adhered to surrounding the conditions in which a blowgun may be used, and which could result in penalties should they be neglected.

Notably:

- The Health and Safety at Work Act 1974 (HSWA), Chapter 37, Section 2, which stipulates that employers must ensure the safety of employees

There are also codes of practice and guidance which should be followed to ensure the safe use of equipment.

These include:

- The Provision and Use of Work Equipment Regulations 1998 (SI 1998/2306) – these include mandatory requirements for employers to pay due care and attention to working conditions and potential risks to health and safety where equipment is used, and also to any additional risks associated with its use

- The Management of Health and Safety at Work Regulations 1999 (SI 1999/3242), which state that employers must carry out a risk assessment and implement appropriate health & safety measures

How to select the right blowgun

Should I choose plastic or metal?

This is down to personal preference.

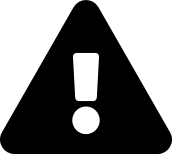

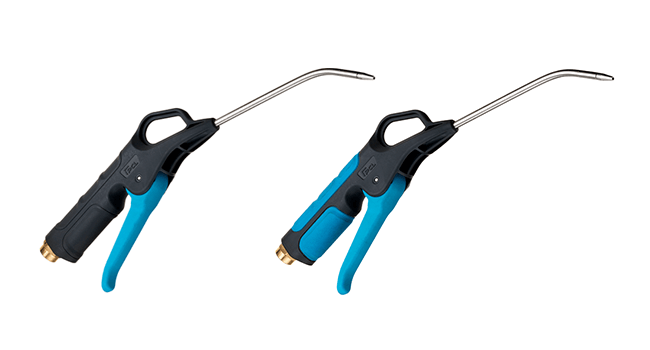

PCL’s latest range of blowguns, ERGO and ERGO EXTREME, are manufactured from Zytel nylon, which is highly durable offering heat and chemical resistance but lighter in weight than metal products and feels warmer in the hand. Nozzles are usually metal, with the internal components made from brass and stainless steel adding to the increased durability and longevity.

PCL’s entry level range of blowguns are also manufactured from plastic, represent excellent value for money but do not have the same high levels of durability as the ERGO and ERGO EXTREME

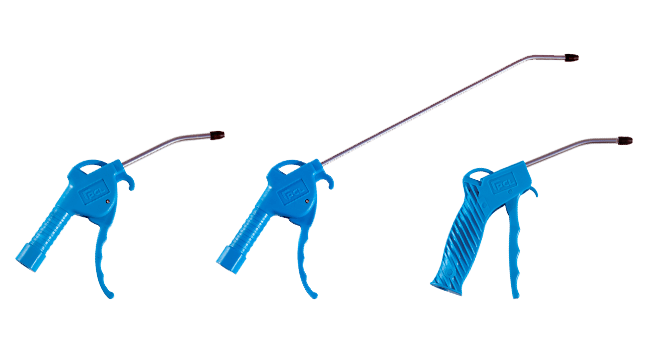

Metal blowguns are more likely to be chosen when longer life is a higher priority than increased comfort, in which case PCL has versions manufactured from die-cast alloy in two styles – pistol or palm – both of which are compact and robust.

|

Pressure required

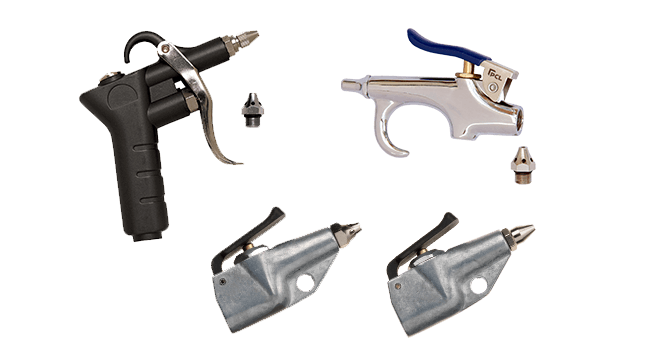

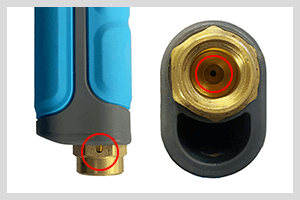

This will depend on the maximum pressure relevant to your air supply and working practices in relation to Health & Safety. Whilst there is no specific UK legislation relating to this, the OSHA states that industrial safety air blowguns should be used for industrial applications. PCL’s safety blowguns feature a cleverly designed safety valve that reduces the output of air to 2 bar and slowly releases air if there is a blockage.

Safety Nozzle Blowguns without a tamper-proof 2 bar valve may be used on a normal factory air supply at 6 bar. However, the manufacturer must be able confirm that pressure from the main nozzle, when blocked, is low enough to mostly reduce the possibility of injury.

|

|

|

|

Blowgun without 2 bar safety valve

|

Blowgun with 2 bar safety valve

|

Type of nozzle

Air nozzles allow the operator to control and optimise the flow of compressed air. To select the most suitable nozzle, you should consider your application.

There are two nozzle types to consider, conical or safety nozzles.

Traditional Conical Nozzles

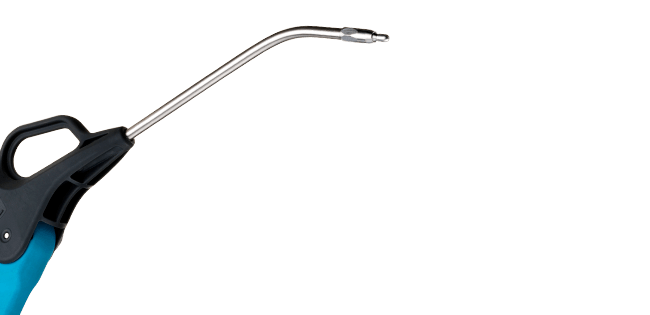

A simple angled nozzle which facilitates access to tight spaces, this traditional conical nozzle is also available as a 9” nozzle which can be further cut and bent to suit individual applications.

For industrial applications, conical nozzles should only be used with a blowgun that has a tamper-proof 2 bar valve. PCL offers conical nozzles with and without the tamper-proof 2 bar valve.

Safety Nozzles

Safety nozzles are designed to prevent blockages, ensuring that the pressure at the main nozzle, in most cases, remains low enough to reduce the possibility of injury.

There are two types of safety nozzles; Aircurtain and Reduced jet-velocity.

Which one you should choose will depend upon the size and shape of the object the air stream is aimed at, as this will dictate whether you need a flat or concentrated pattern of air.

Aircurtain Safety Nozzle (Flat)

An Aircurtain Safety Nozzle will ensure that debris will not fly towards the user. This type of nozzle is central, and incorporates a design that will form a curtain of air shaped like an umbrella around the main air stream. Recommended for use in large areas, an Aircurtain Safety Nozzle is an effective method of drying as it works like a squeegee.

Reduced Jet-velocity Nozzles (Concentrated)

Reduced Jet-velocity Nozzles are equipped with an extension tube with holes surrounding the main nozzle at the bottom, through which atmospheric air is pulled in to increase the volume of air flow whilst also slowing it down. This reduces the risk of debris hitting the user.

PCL offer two types of reduced jet-velocity nozzles:

|

Low Noise Nozzle Designed to reduce the risk associated with noise exposure, meeting OSHA safety standards. |

TURBO Nozzle The TURBO Nozzle is ideal when increased airflow is required |

How to choose the right fitting

It is important to check your input connection type and size to match the air compressor hose. All blowguns in our range have a Rp 1/4 female BSP inlet therefore you will need a R 1/4 male BSP adaptor or hose fitting. Make sure that the adaptor is compatible to the coupling. For a leak-free seal, use a relevant thread sealant.

Unsure which coupling and adaptor series you have? Click to see our handy guide on how to identify a coupling and adaptor profile.

|

|

|

It is the duty of a business to ensure the health and safety of its employees, and this includes making sure the equipment they use is safe, that the user is trained to use it and is aware of associated risks and necessary precautions. Here are some tips to ensure the safe use of air blowguns: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|