Getting compressed air systems up and running safely and efficiently after a shutdown period

After a shutdown period such as Christmas, those needing to restart their compressed air systems will need to check them thoroughly if they’ve been idle for a long period.

Here is our step by step guide to rebooting your compressed air system. Please note, these checks should only be carried out by qualified personnel.

|

|

1. Make sure you have switched off the power supply. Inspecting a compressed air system when the power is on is extremely dangerous. |

|

2. Carry out a visual check of the electrical connections for any signs of damage. |

|

3. Remove the compressor’s panels |

|

4. Carefully view all aspects of the compressor for signs of damage. |

|

|

|

6. Check if the compressor has enough oil, and that the oil is not dirty or discoloured. If it needs topping up or replacing, refer to the manual for instructions. |

|

7. Inspect the inside and outside of the compressor for oil or water leaks. |

|

8. If your system is fitted with either manual or auto drains, open and check them to drain, or ensure they have drained correctly. |

|

9. Make sure there are no contaminants, such as dust or grime, blocking either the inlet or outlet grills. |

|

10. It is advisable to carry out an insulation test on motors for higher powered systems in warm climates, as moisture that may have collected could cause a short circuit on start-up. |

|

11. Look at the air end casing to see which direction the motor and air end pulleys should turn, then check that they are rotating smoothly. |

|

12. Ensure ball valves are correctly configured. |

|

13. Replace the side panels. |

|

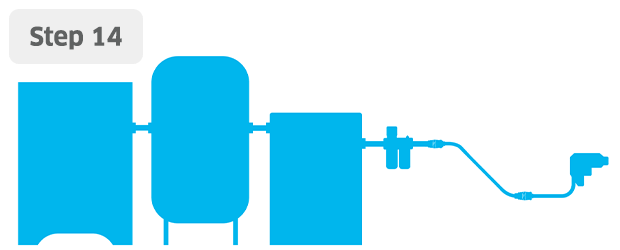

14. At this point you should carry out a final walk round of the system. Check pipework for any potential danger, paying special attention to connections. Inspect the outlet couplings, oil and water separators and filters, and all point of use equipment such as impact wrenches, blowguns, etc - repair and replace where necessary. |

|

|

|

16. Restart your compressed air system. Please note, if you have a water-cooled compressor, you should turn on the cooling water and air blast system on start-up. VSD (Variable Speed Drive) compressors should be left for an hour after the power is back on before being restarted. |

These checks should be carried out following any extended length of time during which a compressed air system has been dormant. Providing these are done thoroughly, with any required maintenance completed, your unit should resume operation at optimum performance with no issues.

5. Ensure all drive belts are in place, with sufficient tension and no sign of wear.

5. Ensure all drive belts are in place, with sufficient tension and no sign of wear.